Dryer Maintenance: How to Replace Drum Bearings

Dryers are essential appliances in our homes, ensuring our clothes are dried efficiently and quickly. Over time, the components inside the dryer can experience wear and tear, leading to issues that may affect its performance. One common problem that dryer owners may encounter is worn-out bearings. The dryer bearings support the clothes dryer drum, allowing it to rotate smoothly during the drying cycle. understanding the importance of maintaining and replacing dryer bearings when needed is key to keeping your dryer running smoothly and effectively. In this guide, we will explore the significance of regular dryer maintenance, focusing on the crucial role of dryer bearings in the proper functioning of a clothes dryer.

|

Table of contents: |

What are Drum Bearings?

Dryer bearings or drum bearings are components within a clothes dryer that provide support and facilitate smooth rotation of the dryer drum. They are essential for the proper functioning of the dryer, as they allow the drum to spin freely while maintaining stability and alignment. The primary function of dryer bearings is to provide stability and proper alignment for the dryer drum. They help to minimize friction between the drum and the dryer cabinet, allowing the drum to rotate freely during the drying cycle. Properly functioning bearings help to prevent excessive wear on the drum and surrounding components, reducing the risk of mechanical issues and maintaining the overall performance of the appliance.

Types of Bearings for Dryers

There are two primary types of bearings commonly found in clothes dryers:

- Drum bearings: These bearings are located at the back or front of the dryer drum, supporting its weight and enabling it to rotate. Drum bearings are typically made of durable materials such as nylon or metal and are designed to withstand the constant movement and load of the drum.

- Dryer wheel bearings: In some dryers, particularly those with a belt-driven drum, wheels or rollers are used to support the drum instead of traditional drum bearings. These dryer wheel bearings serve the same function as drum bearings, providing support and facilitating smooth rotation.

Both types of bearings are crucial for maintaining the stability and balance of the dryer drum. They ensure that the clothes dryer drum rotates evenly, preventing excessive wobbling or vibrations that could lead to noise, wear on other components, and potentially uneven drying of the clothes.

Refer: Parts Of A Dryer: Everything You Need To Know

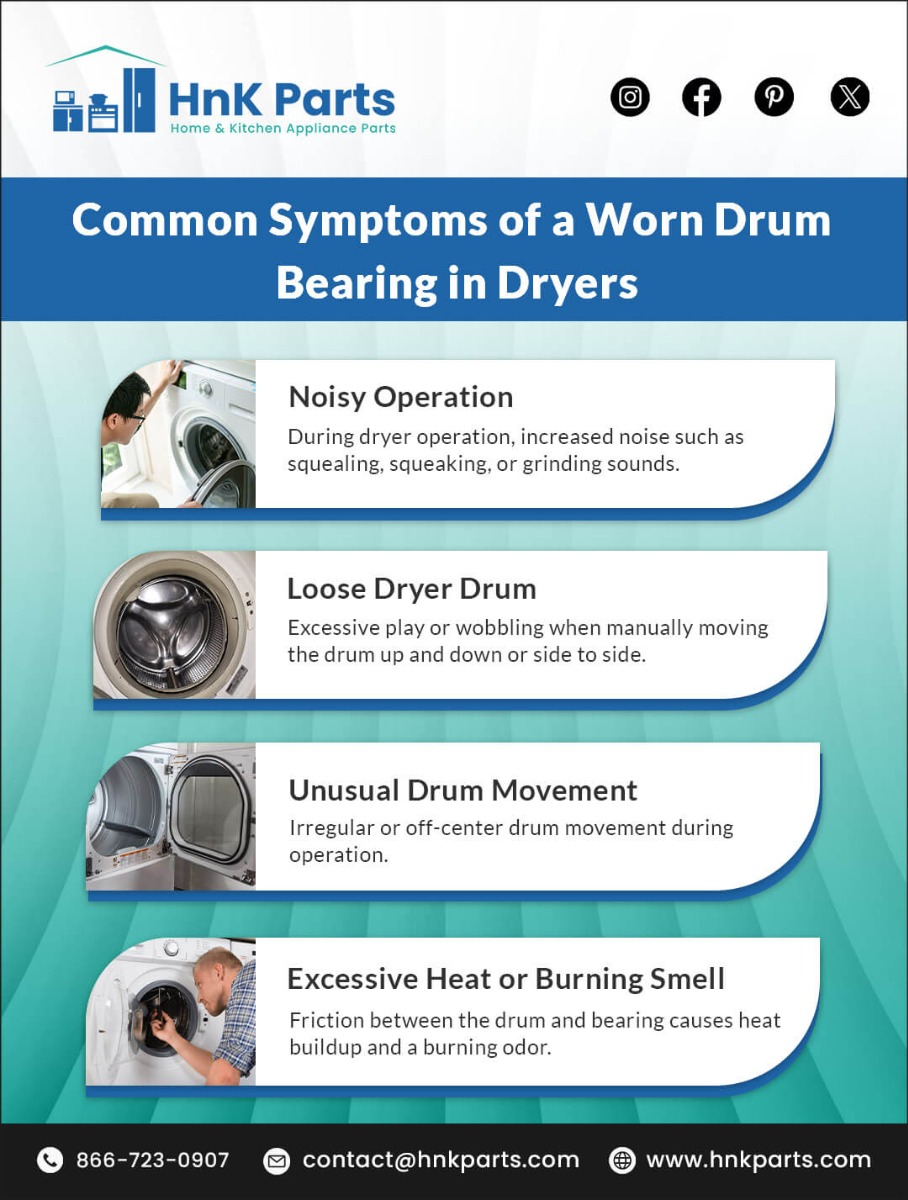

Common Symptoms of a Worn Drum Bearing in Dryers

Essential Tools & Safety Precautions for Replacing Dryer Bearings

Essential tools needed

- Screwdrivers (Phillips and flathead)

- Pliers (adjustable and needle-nose)

- Socket wrench set

- Putty knife or paint scraper

- Needle-nose pliers

- Hammer (for tapping parts if needed)

- Vacuum cleaner (for cleaning dust/debris)

Materials and parts needed

- Dryer bearing kit (compatible with your dryer model)

- Dryer drum seal replacement

- Felt for dryer drum (if applicable)

- Dryer bearing grease (specifically designed)

- Lubricant suitable for dryer bearings (consult manufacturer)

Safety precautions

- Unplug the dryer: Disconnect the power supply before starting any repairs to prevent the risk of electric shock.

- Protective gear: Wear safety gear such as gloves and safety glasses.

- Gloves: Wear heavy-duty work gloves to protect your hands from sharp edges and moving parts.

- Safety glasses: Wear safety glasses to protect your eyes from debris, dust, or small particles during repairs.

Step-by-Step Guide to Replacing Dryer Bearings

Removing the dryer drum

- Unplug the dryer from the power outlet.

- Depending on the model, remove the top panel, front panel, or rear access panel to gain access to the drum.

- Disconnect the drive belt from the motor and lift the drum out of the dryer cabinet.

Inspecting the drum bearing

- Examine the drum bearings for signs of wear, such as excessive play, grinding, or squeaking.

- Check for any visible damage, rust, or deformation of the bearing components.

Replacing the drum bearing

- Remove the old drum bearing by following the manufacturer's specific instructions and using the appropriate tools.

- Install the new drum bearing or bearing kit according to the manufacturer's guidelines.

- Secure the drum bearing in place to ensure proper alignment and support.

Replacing the dryer drum seal

- Remove the old felt seal from the dryer drum, ensuring that the surface is clean and free of debris.

- Install the new dryer drum seal securely, ensuring a proper fit and alignment to prevent air leaks.

Installing dryer drum glides

- If applicable to your dryer model, carefully replace or install dryer drum glides to facilitate smooth movement of the drum.

- Ensure that the glides are positioned correctly and secured according to manufacturer specifications.

Reassembling the dryer

- Carefully place the drum back into the dryer cabinet, ensuring it rests properly on the drum support rollers or glides.

- Reattach the drive belt to the motor and return any removed panels or access covers to their original positions.

- Plug the dryer back into the power outlet and test its operation to ensure the bearings and seals are functioning as intended.

Troubleshooting and Tips for Replacing Dryer Bearings

- Check for proper alignment: Ensure that the drum is correctly seated on the support rollers or glides. Adjust the positioning of the drum and verify that it is aligned and balanced within the dryer cabinet.

- Inspect the drive belt: Check the condition of the drive belt. A worn or stretched-out drive belt can cause the drum to wobble. If necessary, replace the drive belt with a new one to restore proper tension and support.

- Verify bearing installation: Double-check the installation of the new drum bearings. Ensure that they are securely fastened and aligned according to the manufacturer's specifications.

- Squeaking or grinding noises: If the dryer continues to produce squeaking or grinding noises after replacing the bearings, inspect the bearing assembly and surrounding components for proper installation.

- Irregular drum movement: If the drum exhibits irregular movements or vibrations, re-examine the alignment of the drum within the dryer cabinet. Check dryer drum loose alignments that may be affecting the drum's rotation.

- Air leaks: Following the replacement of the clothes dryer drum seal, verify that there are no air leaks around the drum. Properly sealing the drum is essential for efficient and effective drying.

Maintenance Tips for Longevity of Dryer Bearings

|

Tip |

Description |

|

Regular inspection |

Periodic checks of the dryer drum and bearings to ensure longevity and optimal performance. |

|

Visual inspection |

Examine drum bearings for signs of wear, damage, or misalignment. Look for unusual noises, excessive wobbling, or irregular drum movements. |

|

Check for debris |

Inspect the area around the drum bearings for lint, dust, or debris. Clear any obstructions to prevent interference with drum rotation. |

|

Verify drum alignment |

Ensure the dryer drum is properly aligned within the cabinet. Irregular drum movement may indicate issues with bearings or support components. |

|

Cleaning and lubrication |

Routine maintenance practices to keep bearings and drums in good condition. |

|

Cleaning |

Regularly clean the drum bearings and surrounding components to remove lint, dust, and debris. Use a vacuum or soft brush to gently clean the area. |

|

Lubrication |

Follow the manufacturer's recommendations for lubricating the dryer bearings. Apply lubricant as directed to maintain proper functionality. |

Checkout: How To Clean A Dryer: 9 Easy Steps

Maintaining your dryer's bearings is essential for ensuring its smooth and efficient operation. By following the steps you can replace worn or defective bearings and prolong the lifespan of your dryer, saving on potential repair costs and avoiding inconvenience. Remember to always refer to your specific dryer model's manual and seek professional assistance if you encounter any challenges or are unsure about performing the replacement yourself. Regular maintenance and timely repairs will not only keep your dryer running smoothly but also contribute to a safer and more energy-efficient home. HnKParts offers a wide range of dryer parts and bearings. Get the best quality accessories now to meet all your needs.

FAQs

How do I replace the felt on my dryer drum?

To replace the felt on your dryer drum, you will need to access the drum by removing the dryer's front panel. After removing the old felt seal, thoroughly clean the area before installing the new felt seal.

My dryer drum feels loose, what should I do?

If your dryer drum feels loose, it may indicate issues with the drum support rollers, glides, or the drum bearing. Check for proper alignment and fit of these components.

How do I replace the bearings in a front load dryer?

Front load dryer bearing replacement involves accessing and removing the dryer drum, then identifying and replacing the worn bearings. It's important to follow the manufacturer's guidelines.

What is the best lubricant for dryer bearings?

When lubricating dryer bearings, it's important to use a lubricant specifically designed for this purpose. Dryer bearing grease is often recommended to ensure proper lubrication and minimize friction within the bearing assembly.