How to Replace a Washing Machine Transmission: Cost & Steps Explained

Your washing machine is a cornerstone of modern convenience, silently tackling mountains of laundry to keep your household running smoothly. However, like any hardworking appliance, it has intricate internal components that can wear down over time. One such vital part is the washing machine transmission. When this critical component begins to fail, it can bring your laundry routine to a screeching halt, leaving you with a pile of unwashed clothes and a sense of frustration. Understanding the signs of failure, the options for washing machine transmission repair versus replacement, and the associated costs is essential for any homeowner. This comprehensive guide will walk you through everything you need to know about your washing machine's transmission, from diagnosing issues to the detailed steps on how to replace the washing machine transmission yourself, ultimately saving you time and money.

What is a Washing Machine Transmission?

The washing machine transmission is a complex mechanical assembly responsible for transferring power from the motor to the agitator and the spin basket. It allows the washing machine to perform its two primary actions: agitating (moving clothes back and forth in water) and spinning (removing water from clothes by rapidly rotating the drum). Essentially, it's the gearbox that manages the different speeds and motions required for various wash cycles. Understanding how does a washing machine transmission work is key to comprehending its importance; it enables the machine to switch between the slow, oscillating motion of agitation and the high-speed rotation of the spin cycle, ensuring your clothes are thoroughly cleaned and efficiently dried.

Signs of a Failing Washing Machine Transmission

Recognizing the symptoms of a failing washing machine transmission can save you from a complete breakdown and potentially minimize the washing machine transmission cost of repairs.

|

Symptom |

Description |

|

Loud noises during operation |

|

|

Failure to agitate |

|

|

Failure to spin |

|

|

Burning smell |

|

|

Leaking oil or grease |

|

|

Machine shaking violently |

|

|

Difficulty changing cycles |

|

Washing Machine Transmission Repair vs. Replacement Considerations

Once you suspect a faulty washing machine transmission, the next crucial decision is whether to pursue washing machine transmission repair or opt for a complete replacement of the appliance.

-

Age of the appliance: A general rule of thumb is that if your washing machine is older than 8-10 years and the washing machine transmission has failed, replacement might be the more economical choice.

-

Cost of repair vs. new unit: Research the average washing machine transmission cost for a new transmission part and the labor involved. Compare this to the price of a brand-new washing machine with similar features. If the repair cost approaches or exceeds 50% of the cost of a new machine, replacement is generally recommended.

-

DIY skill level: If you're considering how to replace a washer yourself, be honest about your mechanical skills. It's a complex job that requires patience and specific tools.

-

Warranty status: Check if your washing machine is still under warranty. If so, the washing machine transmission repair might be covered, significantly reducing your out-of-pocket expenses.

-

Energy efficiency: Older washing machines are often less energy-efficient than newer models. Replacing a very old machine with a new Energy Star-rated one can lead to long-term savings on your utility bills, offsetting some of the initial washing machine transmission cost

Essential Tools and Parts Needed

If you've decided to tackle the replace washing machine transmission project yourself, gathering the right tools and the correct replacement part is paramount.

-

Socket set: Various sizes will be needed for bolts and nuts.

-

Nut drivers: For hexagonal head screws.

-

Screwdrivers: For various fasteners.

-

Pliers: For gripping and manipulating small parts or wires.

-

Adjustable wrench: For larger nuts or as a general-purpose wrench.

-

Putty knife or flat-blade screwdriver: For prying open console clips.

-

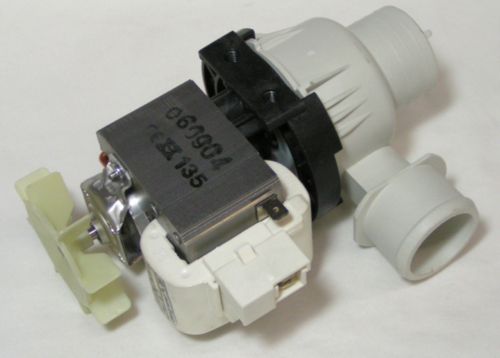

New washing machine transmission: Ensure you purchase the exact replacement washing machine transmission for your specific washing machine model. Check the model number and serial number of your appliance carefully when ordering.

-

Transmission gasket/seal kit : Some transmissions come with new gaskets, but if not, it's wise to replace the seals to prevent future leaks.

-

Washing machine clutch: If your washing machine has a clutch assembly, inspect it for wear. If it's worn, consider replacing it at the same time, as you'll already have the machine disassembled.

How to Replace a Washing Machine Transmission

Replacing a washing machine transmission is a challenging but doable DIY project for those with mechanical aptitude. Before beginning any work, always unplug the washing machine from the power outlet and turn off the water supply valves. Disconnect both hot and cold water hoses.

-

Drain water: Ensure the machine is completely drained of water. If there's standing water, manually drain it or run a spin cycle if possible.

-

Disconnect hoses and power: Unplug the machine. Turn off the hot and cold water supply valves and disconnect the water inlet hoses from the back of the machine. Disconnect the drain hose from the standpipe or sink.

-

Move the machine: Carefully pull the washing machine away from the wall to give yourself ample working space. You may need an appliance dolly.

-

Remove back panel: Some models require removing the back access panel to gain access to internal components.

-

Remove the control console: Locate the clips or screws holding the control console to the main cabinet. Use a putty knife or screwdriver to release the clips, or unscrew them. Gently lift and flip the console over, being careful not to strain any wires. You may need to disconnect a few wiring harnesses.

-

Remove the cabinet: The outer cabinet is usually held by clips or screws. Release these. The cabinet can then be lifted off or unlatched and folded away. This will expose the inner workings of the washer.

-

Remove the agitator: Inside the tub, you'll see the agitator. Most agitators are held in place by a single bolt at the bottom. Use a deep socket to remove this bolt. Then, pull the agitator straight up to remove it. It might be stuck; you can gently rock it side-to-side to loosen it.

-

Remove the inner wash basket (Tub): The inner basket usually sits on a hub that connects to the transmission. There might be a large spanner nut holding the basket in place. You'll need a special spanner wrench for this. Once the nut is removed, carefully lift the inner basket out of the outer tub.

-

Remove the outer tub and motor assembly: Depending on your model and how the washing machine transmission is mounted, you might need to remove the entire outer tub. This often involves disconnecting the suspension rods, hoses, and wiring. The motor is typically attached to the transmission, often bolted together.

-

Access the transmission: With the tubs removed, the washing machine transmission will be accessible, usually located at the very bottom center of the machine. It will be bolted to the frame.

-

Replacing the washing machine transmission: Carefully label and disconnect any electrical wiring harnesses leading to the transmission, motor, or other components that are attached to the transmission. If your machine has a drive belt connecting the motor to the transmission, remove it.

-

Install the new transmission: Position the new washing machine transmission in place. Align the mounting holes and secure it with the bolts you removed earlier.

-

Reconnect the drive belt and electrical connections: Reinstall the drive belt and reconnect all the electrical wiring harnesses, ensuring they are connected to the correct terminals based on your labels or photos.

-

Testing: Run a short, empty cycle to check for proper operation, leaks, and unusual noises. Pay close attention to how the machine agitates and spins, confirming that your replace washing machine transmission effort was successful.

How to Drain a Washing Machine Fast & Easy

Cost Breakdown: Washing Machine Transmission Cost

The washing machine transmission cost can vary significantly depending on whether you opt for a DIY replacement or hire a professional, as well as the brand and model of your machine.

-

Part cost: Prices typically range from $150 to $400, but can go higher for specialized or high-end models. For instance, the washing machine transmission cost for a common GE or Whirlpool model might be at the lower end, while less common brands could be more expensive.

-

Miscellaneous supplies: Gaskets, seals, or lubricants might add another $10-$30.

-

Total DIY estimated cost: Roughly $160 to $580. This is the most budget-friendly option if you have the skills and time.

-

Labor: This is where the bulk of the professional washing machine transmission repair cost comes in. Replacing a washing machine transmission is labor-intensive, often taking 2-4 hours or more. Appliance repair technicians typically charge $75 to $150 per hour.

-

Total professional estimated cost: The total cost to replace the transmission in a washing machine by a professional can range from $350 to $700+, depending on your location, the specific technician's rates, and the complexity of your machine.

When considering the washing machine transmission cost, remember to weigh the repair cost against the cost of a new washing machine. Entry-level new washing machines start around $500-$700, while mid-range models can be $800-$1200. If the repair approaches the cost of a new, basic machine, it might be more prudent to invest in a new, more energy-efficient appliance.

Maintenance Tips to Extend Transmission Lifespan

Proper maintenance can significantly extend its lifespan and potentially delay the need for washing machine transmission repair or replacement.

-

Avoid overloading: Overloading your washing machine puts immense strain on the motor, agitator, and especially the washing machine transmission. Always adhere to the manufacturer's recommended load size.

-

Balance loads: Unevenly distributed loads can cause the machine to shake violently during the spin cycle. This excessive vibration puts stress on the transmission, bearings, and suspension system.

-

Check for foreign objects: Before washing, check pockets for coins, keys, or other small items. These can fall out during the wash and get lodged in the pump or even the transmission area, causing damage.

-

Use the correct cycle settings: Use the appropriate wash cycle for the type and weight of your laundry. Using a heavy-duty cycle for a small, delicate load is unnecessary and puts extra strain on the moving parts, including the washing machine transmission.

-

Clean regularly: Periodically clean the agitator and the tub. Buildup of detergent residue, lint, or hard water deposits can affect the balance and efficiency of the machine, indirectly impacting the transmission.

-

Address small issues promptly: If you notice new noises or minor performance issues, investigate them early. Addressing a minor problem, such as a loose pulley or a failing bearing, can prevent it from escalating into a major washing machine transmission issue.

By following these simple maintenance practices, you can maximize the life of your washing machine transmission and keep your appliance running efficiently for years to come.

Common Washing Machine Issues and How to Solve Them

While diagnosing a failing transmission can be daunting, understanding the common signs and symptoms, such as grinding noises or a failure to agitate or spin, empowers you to make informed decisions. Whether you choose to take on the challenging but rewarding DIY project of how to replace washing machine transmission yourself or opt for professional washing machine transmission repair, being knowledgeable about the process and the expected washing machine transmission cost is invaluable. Regular maintenance, such as avoiding overloading and ensuring balanced loads, can significantly prolong the life of your washing machine transmission, preventing premature wear and saving you money in the long run.

HnKParts is the one-stop solution for all your home appliance needs. We offer a vast selection of washing machine replacement parts near you online. It includes motors, hoses, agitators, timers, and much more

FAQs

What does a bad washer transmission sound like?

A bad washer transmission often makes grinding, clunking, or loud whirring noises during the spin or agitation cycle.

How to check if the transmission is blown?

To check if the washer transmission is blown, inspect for burning smells, oil leaks, or lack of movement during the wash and spin cycles.

How long does it take to replace a transmission?

Replacing a washer transmission typically takes 1 to 3 hours, depending on the model and technician experience.